Like our car, scuba equipment also needs maintenance.

Like a car needs new filters, fresh oil and spark plugs, our scuba equipment needs new filters, o-rings and grease.

Only washing the car doesn’t let it drive good for a long time. Same applies for our scuba gear. When we don’t maintain our gear it will start to breath heavier or it starts blowing air uncontrolled.

The filters get dirty, the O-rings dry out and some other parts wear out. No matter how good we wash our gear, dirt, chalk and corrosion always become part of the inside of all scuba equipment. That’s why it’s smart to remove that and replace worn out parts before you will get in trouble during a dive.

The easiest way to maintain scuba equipment is to bring it to a so called ‘expert’, like most people also do with their car and scuba gear.

But as we all know, those ‘experts’ aren’t always real experts. Like in a car garage there are also bunglers in the scuba world. I had 3 bad experiences with that kind of ‘experts’ before I decided I would go learn how to do it myself.

If you want it done real good, you have to do it yourself.

The first bad experience was with an older Mares MR22 and Abyss set. The first time in the water with it the Abyss started blowing air like crazy when out of my mouth. Luckily one of my mates had a middle pressure gauge with him. That little thing told us the MR22 first stage was set to 12bar/175psi middle pressure. That’s WAY too high for an Abyss. That must be in between 9,5bar/135 psi and 10bar/142psi ideal. Like in the picture below.

The second bad experience was with the same set, at another dive center and of course another ‘expert’. I had told him explicit I wanted the middle pressure at 9,8bar/138psi and told him the reason for that. He said he understood completely. After the first dive after that ‘maintenance’ the Abyss started to blow air uncontrolled again. This time the middle pressure was perfect, like I asked for, so me and my mate opened the Abyss. The first thing we saw was the old rubber poppet seat. The ‘expert’ had just turned the old 50 cent rubber poppet seat around.

The last bad experience was with my Mares MR32 ice, also with an Abyss second stage.

Everyone who’s a bit familiar with the Mares regulators knows there’s a small valve in the first stage, what needs to be replaced after about 3 or 4 times maintenance. I told the so called ‘expert’ that was the 4th time maintenance, so it needed a complete overhaul that time. He told me he would do that for me and charged me also for a complete overhaul. After 4 dives after the ‘overhaul’ with that set the octopus began blowing like crazy. Testing the middle pressure, like I already had learned to do first in a situation like that, told me that was over 14bar/200psi. That can only mean 1 thing; that little valve is worn out. That’s impossible in 4 dives, so I went back to the ‘expert’, who told me he had replaced it, but would do it ‘again’ for me. I had to pay again for that valve and his ‘work’.

That was it for me. I decided to do some courses to learn how to maintain my equipment myself.

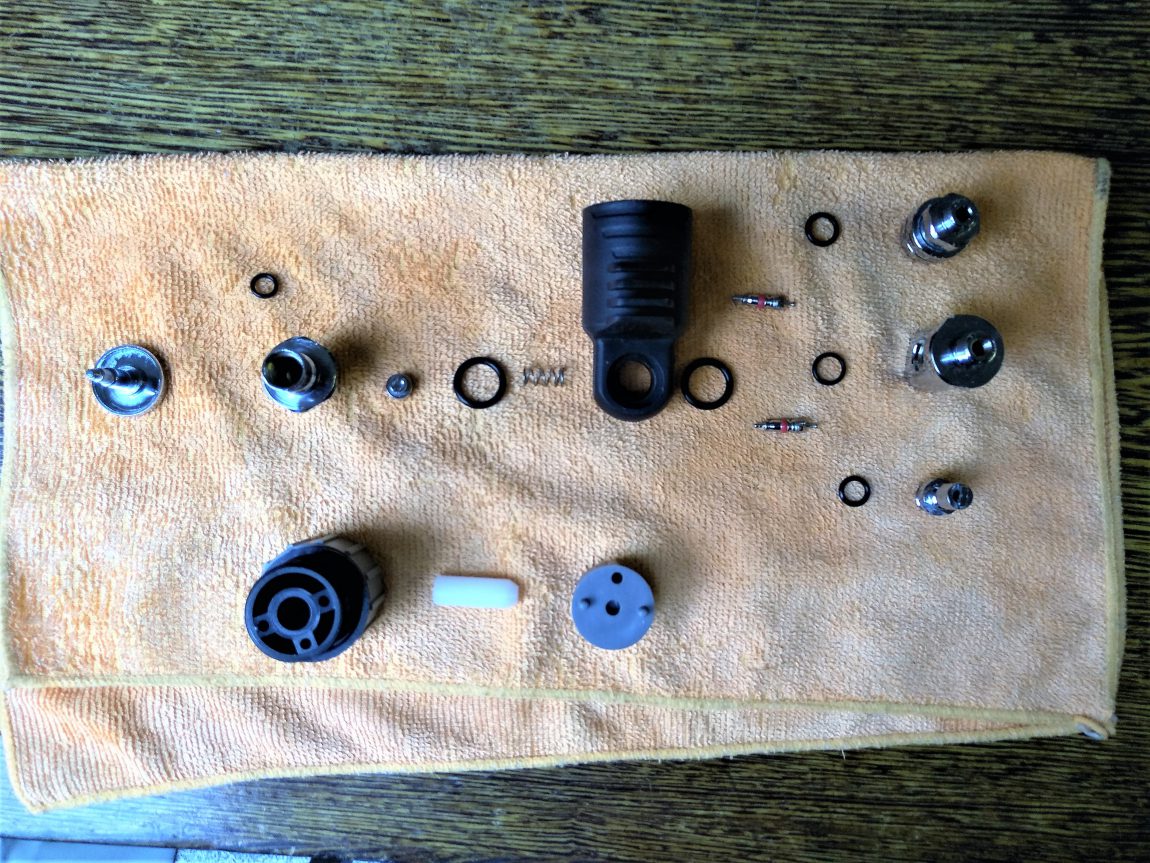

It turned out to be much easier than maintaining my own car. Scuba gear only contains just a few parts, what you have to remember where to put back, or just make a picture like above. Than you don’t even have to remember. Just look at the picture how it has to go back in.

The second stage is even easier to service than a first stage. There’s way less parts in and you can almost do nothing wrong as long as you know what you are doing.

Please don’t go try and DIY if you never had any lessons in servicing scuba gear. The smallest mistake can have fatal consequences.

Maintenance isn’t only the regulator set.

Also the BCD has parts what need maintenance at least every year or after 100 dives. Especially the inflator is a very important device what has to work perfectly, it has about 5 or 6 O-rings what can and will dry out and some metal parts what can and will corrode. That’s why it’s very important to service it and replace all O-rings every time. You don’t want to become without air in your BCD when at the surface, but also not during a dive.

That’s why you also have to maintain the dump valves at the same time. They’re even more easy to maintain. Screw them off while holding the dump cord tight and soak them in a good cleaner for at least a hour. Brush the spring in it, look at the rubber at the valve real good and replace that when you think it starts to dry out just a little.

Even the less important scuba gear needs maintenance if you don’t want it to fail.

Even a horn for on the inflator will stop making noise if you do’t maintain it. Just clean it on the outside isn’t enough for a long life.

As you can see in the next picture even a horn has many parts what can wear out.

My horn has 6 O-rings what can and will dry out over time, a spring what gets dirty and corroded and 2 little valves like the valves in a car tire.

Never forget to maintain the air tank and it’s valve.

The tank itself can only corrode on the inside when we put in dirty moist air. The outside of the tank we can always see, so we can check that for corrosion regularly. The inside we can only see and inspect when we take of the valve out.

As you can see in the picture above, my tank valve can handle a double setup and it has an insert for the INT setup. That’s why it has a few more components than a standard valve.

I take of the valve once a year to inspect the tank on the inside, clean all components of the valve and change all O-rings. Most O-rings are still in great condition after a year, but sometimes one or a few aren’t as round as a new one anymore. I just don’t want to take any risk for the few cents those O-rings cost.

Diving light

Even our diving lights need some maintenance every year or 100 dives. Especially when we dive in salt waters the O-rings will dry out sooner than we would want them to do.

Also a halogen light bulb will give less light after a while and the batteries don’t have eternal life too. That’s why I test the batteries at least once a year and change them when they lost half of their capacity. Because I use NiCD batteries in my Metalsub light that’s about once every 7-8 years. Almost the same time as a Osram Halostar bulb takes to go down about 10% of it’s output.

Because the original accu packs from Metalsub are very expensive I make those packs myself, out of professional D-cell 9000mAh cells, just like Metalsub also uses.

The only difference between my packs and the Original is that Metalsub connects the batteries by metal strips what they spot weld on the batteries, with a very high current, is that I I glue them together, with silver glue, what I also use to repair electronics.

I use the same heat shrink tubing as Metalsub to hold the batteries together and the same hot glue to hold the 2 bars together. Making such a battery pack cost me about 5 minutes, but saves about half the money.

MicDiver©

.